Centrifugal fans

Operating principle is a combination of two effects: centrifugal force and again deflection of the airflow by the blades, the deflection is from a radially outward direction into a spiral flow pattern.

Centrifugal fans normally produce more static pressure than axial-flow fans of the same wheel diameter and the same running speed because of the additional centrifugal force which is missing in axial-flow fans. Since in centrifugal fans the airfoil lift contributes only a small portion of the pressure produced.

There are six types of centrifugal fan blades in common use.

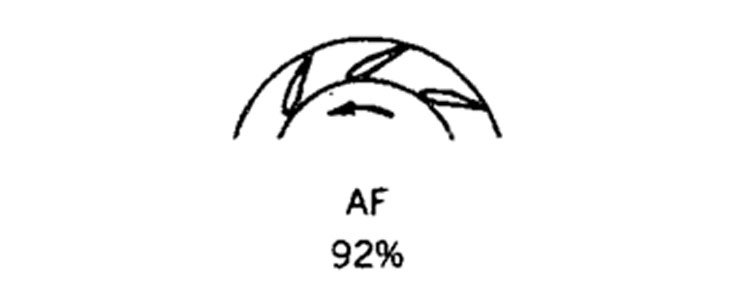

1. Centrifugal Fans with Airfoil (AF) Blades

It has the best mechanical efficiency and the lowest noise level of all centrifugal fans.

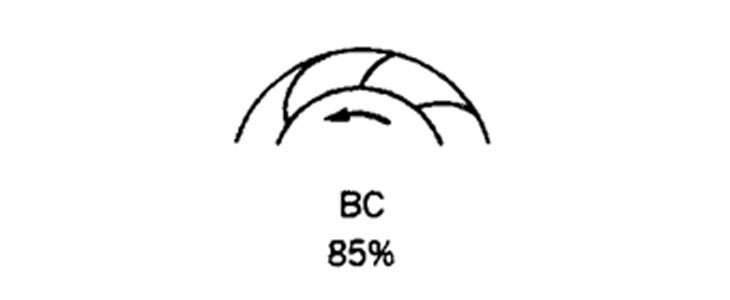

2. Centrifugal Fans with Backward Curved (BC) Blades

BC blades are single thickness steel blades but otherwise are similar to AF blades with respect to construction and performance. They have slightly lower efficiencies but can handle contaminated air streams because the single thickness steel blades can be made of heavier material than can be used for hollow airfoil blades.

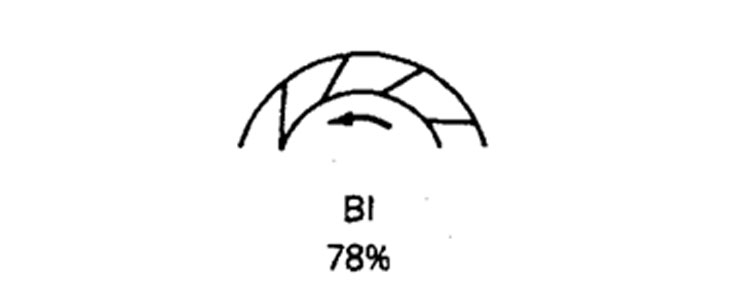

3. Centrifugal Fans with Backward Inclined (BI) Blades

More economical in production but they are somewhat lower in structural strength and efficiency.

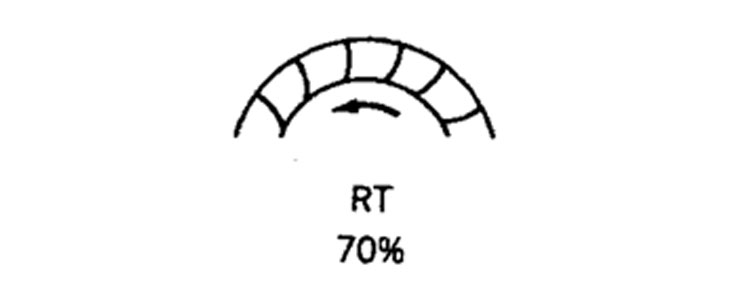

4. Centrifugal Fans with Radial Tip (RT) Blades

RT Blades are curved, with good flow conditions at the leading edge. Only the tips are radial, as the term radial-tip blades indicates. RT Wheels are used mainly in large sizes for industrial applications, often with severe conditions of high temperature and light concentrations of solids.

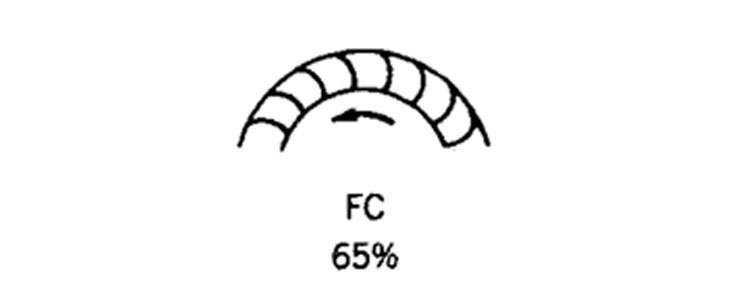

5. Centrifugal Fans with Forward Curved (FC) Blades

The blades are curved forward in the direction of the rotation. Due to very large blade angles and in flow rates that are much larger than those of any other centrifugal fans of the same size and speed. Mostly use in small furnaces, air conditioners and electronic equipment whenever compactness is more important than efficiency.

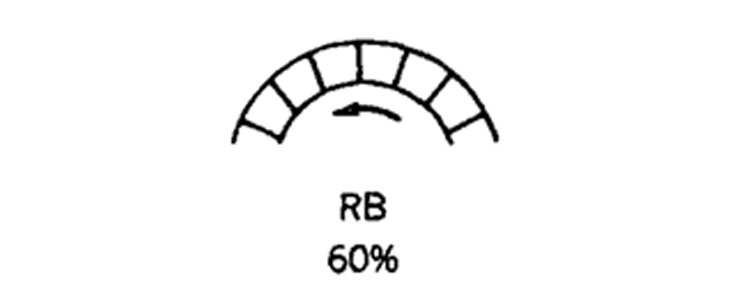

6. Centrifugal Fans with Radial (RB) Blades

Radial blades (RBs) are rugged and self-cleaning, but they have comparatively low efficiencies because of the nontangential flow conditions at the leading edge.

Industrial Centrifugal Fans (Industrial Exhausters)

Most of the manufacturers offer these units with a choice of the following four different wheel types for blowers in each size:

- Air handling (AH) wheels (back plate, shroud, 8/10/12 BI blades)

- Material Handling (MH) wheels (back plate, shroud, 6 RB blades)

- Long-shavings (LS) wheels (same as MH, but no shroud)

- Long-shavings open (LSO) wheels (no back plate, no shroud, 6/8 radial blades)

High Pressure Blowers

Mostly RB Blades are used in this type of centrifugal fan. In which the blades are narrow so it has more structural strength, and so it can run at higher speed and generate high pressure.

Application of High-Pressure Blowers and Exhausters

- Pneumatic conveying of agriculture grains and other materials

- Aeration of waste water, molten iron and other fluids

- Central vacuum cleaning systems

- Gas boosting

- Combustion air

- Air flotation systems

- Various industrial processes